Arab Hookah charcoal forming machine

- Arabian hookah charcoal forming machine

- Silver carbon forming machine

- Arabia hookah charcoal automatic production line

- Carbon rod forming machine

- Hookah charcoal molding machine

- Toner molding machine

- Automatic cutter finished

- Stamping bar making machine

Hookah charcoal other equipment

- Tablet machine

- Ball press machine

- Raymond Mill

- Spiral hookah charcoal machine

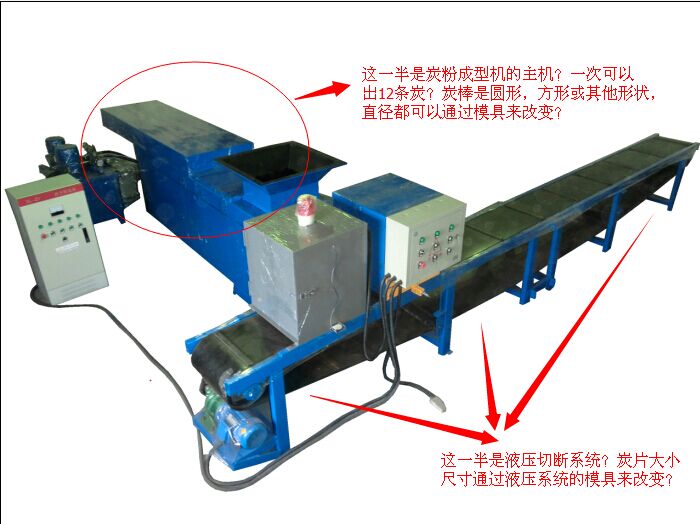

- Carbon powder forming machine

- Wheel grinding machine

- Hydraulic hookah charcoal tablet press

- Rotary hookah charcoal tablet press

Aerated Concrete Equipment

Contact Us

- E-mail: 1430396450@qq.com

- WhatsAPP: +0086 13849118395

- Tel: 0086-13849118395

- Contact: Mr. Li

- Q Q: 1430396450

- Wechat: 0086 13849118395

- Address: Gongyi City Longwei Industrial Park, Zhengzhou, Henan, China

Carbon powder molding machine automatic production line equipment in the carbon products in the industry

Charcoal industry, generally use the former; After a molding, carbonization process route. After carbonization molding, the sawdust is dried to 6 ~ 12%, and then the system's rod material machine is pressed into rods with a diameter of 45 mm and 30 cm, and then the raw materials are piled up in the kiln for combustion, and then made into a cooling vessel. The current problems facing the industry are: high cost, low production capacity, low profit, and the main reason is due to carbonization "after" the formation of the technical route. It is raw material drying, consumption, time consuming, consumable. Due to the high humidity requirements of the machine on raw materials, the relative humidity of the molding is limited to 6 ~ 12%, so the raw materials must be dry. According to experienced friends, the production of a ton of charcoal, dry sawdust this process takes two hours 200 ~ 300 KWH, coal 400 kg. Second, the propeller of the machine is badly worn and needs welding for two to three days to repair. Because sawdust is viscous at high temperature, it needs to be heated to a certain temperature when forming to produce a certain hardness and density of the bar, so the wear is very serious. It is not economical to take out the propeller for welding, and it is necessary to buy special welding equipment and welding work, which also leads to the increase of labor cost. Thirdly, a large amount of carbonized materials need to be burned in the furnace for 7 ~ 8 days. The carbonization technology mastered by burner is strong, and the output and quality are not guaranteed. In the process of drying, coking and pyrolysis of carbon formed in the carbonization layer, the heat transfer is slow through materials with relatively high density, so it needs to be heated slowly. Otherwise, cracks, broken bars and even breakage are likely to occur. Because combustion carbonization method is a natural type, not only to ensure enough carbonization temperature, need enough oxygen, but also to prevent excessive coking, charcoal burning ash, need to control oxygen supply. This requires kiln owners to rely on experience to decide when to supply oxygen, how much oxygen to give, how fast to heat, and when to control oxygen supply for heat preservation. Therefore, some experience cannot guarantee stability and depends too much on individuals.